There we installed a fel pro split seal in a big block chevy engine.

Rope rear main seal install.

To photograph the proper procedures for installing a rear main seal we visited with larry lempicki of pro motion engines in east hanover new jersey.

The rear main rope seal worked well in its time as long as you completely understood the installation process.

For the rope seal procedures we went to jim taylor engine service in phillipsburg new jersey.

But a rubber rear main seal requires much closer engine machining tolerances.

It should protrude by approximately 0 3 0 5mm at each end but don t either stretch the seal by too much and make it protrude by more than this distance or work it too far in and.

Removes and installs upper rear main seals without dropping crankshaft.

It s leaking oil badly through the rear main seal.

Rubber replacement seals if available may be the cure for some engines that originally used rope rear main seals.

The correct way to install the rope seal is with the engine out and crank removed make sure the crank surface where the seal rides is smooth without pits and gouges.

I do not want to take out the crank shaft unless absolutely necessary.

This marvelous material is easy to trim.

6100 graphtite rope rear main seal.

Our rope actually fits.

Can i replace the rope seal with a rubber slip lip seal comes in 2 halves and is very easy to install.

Also the installation technique of a rear main rope seal was slowly being lost as they diminished in use.

To install new seal 27000 includes a pulling wire with a removable t handle and spring steel clip that grips the seal firmly as it is pulled into.

So using a rear main rope seal is almost a thing of the past and has greatly diminished in use.

The lisle 27000 includes everything needed to speed up a long slow job.

Graphtite rope seals are miles ahead of any other rope seal out there.

Cork screw puller makes it easy to remove old seal.

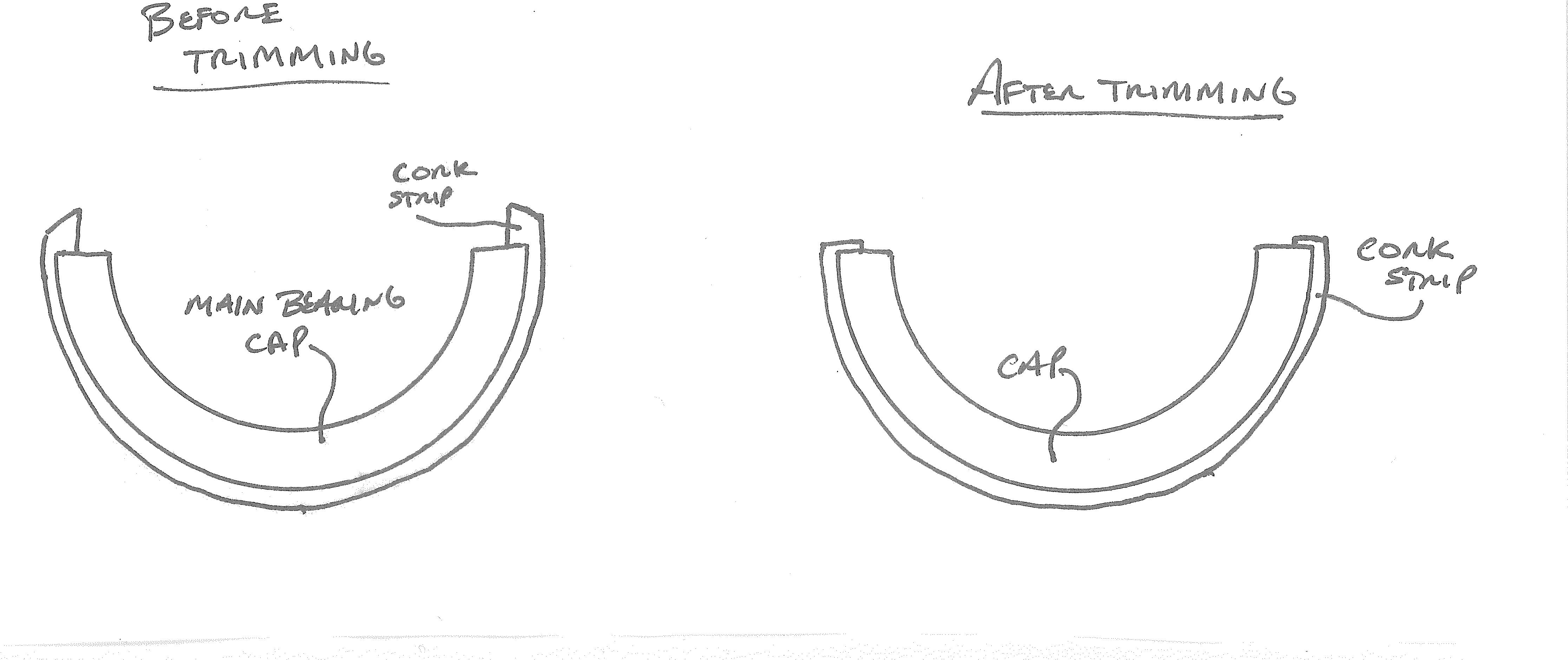

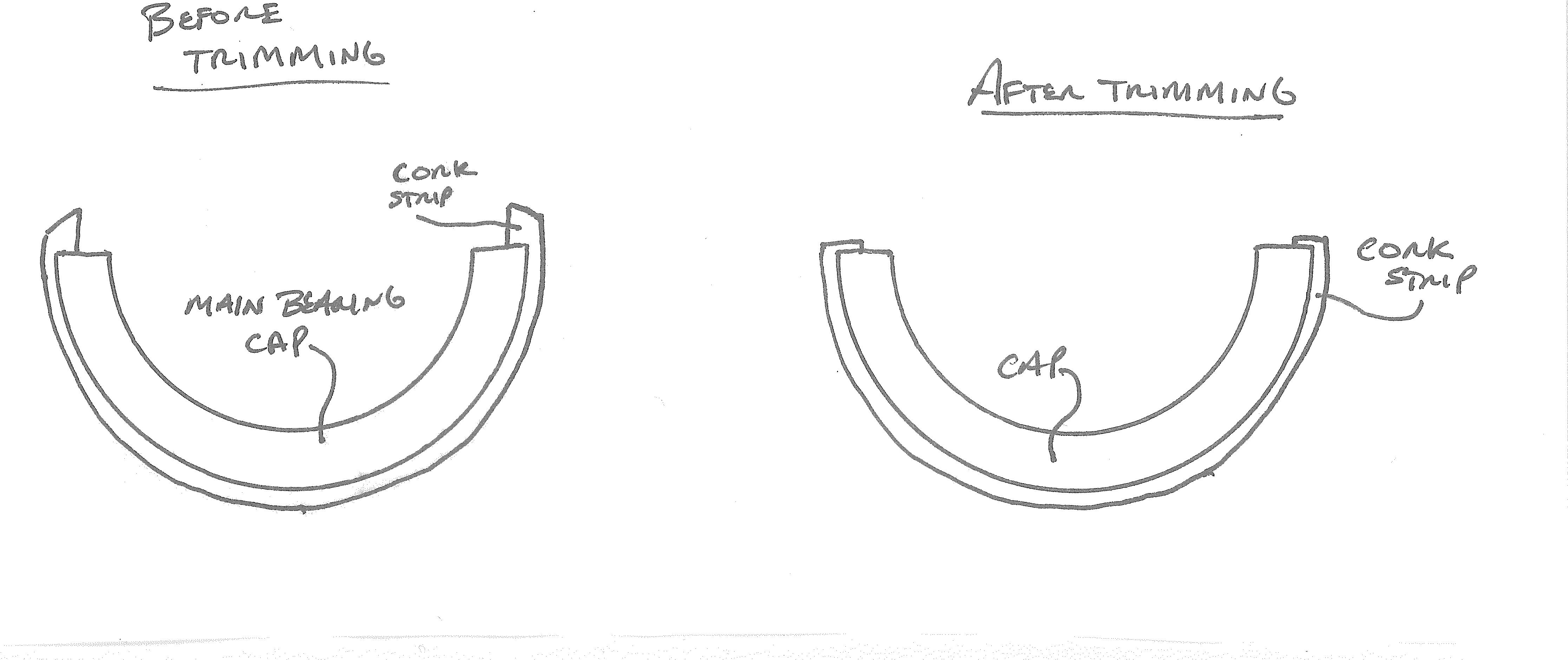

To ensure exact trimming each kit includes installation instructions a special knife and a few other trimming aids.

Once the seal is placed into position use a round edged tool such as a pin punch to work the seal into its groove keeping it protruding equally at both ends.